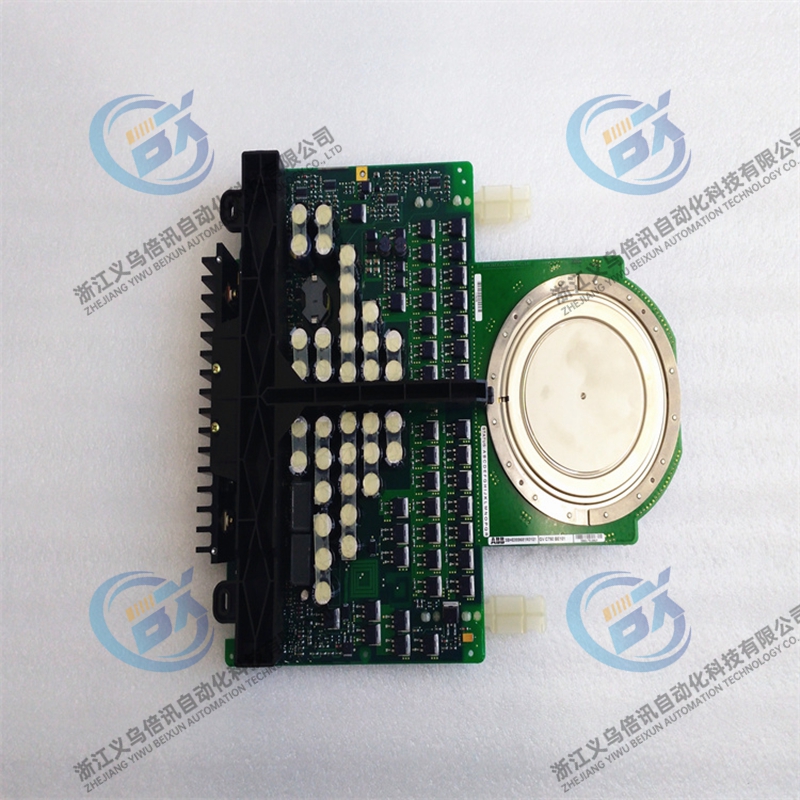

ABB DSQC679 3HAC028357-001操作器

主要特点: * 高精度测量和控制:该操作器具有高精度的测量和控制功能,能够满足各种工业应用的需求。 * 易于使用:该操作器配备了直观的图形用户界面,支持触摸屏和键盘输入,方便用户进行参数设置和操作。 * 强大的数据处理能力:该操作器内置了大容量存储器和高速处理芯片,能够快速处理各种数据,并进行实时分析和决策。 * 兼容性强:该操作器支持多种通信协议,如以太网、串行接口等,方便与其他设备进行数据交换和通信。 应用领域: 该操作器适用于各种工业应用场景,如石油、化工、电力、冶金、纺织等。它能够实现对各种工业过程的精确控制,提高生产效率和产品质量。 工作原理: ABB DSQC679 3HAC028357-001操作器通过传感器采集工业现场的数据,经过处理和分析,生成控制指令,实现对工业过程的精确控制。该操作器还具有自我诊断和报警功能,能够及时发现异常情况并采取相应的措施。 硬件组成: 该操作器主要由微处理器、传感器、存储器、通信接口等组成。其中,微处理器是操作器的核心,负责数据处理和指令生成;传感器负责采集工业现场的数据;存储器用于存储数据和程序;通信接口则用于与其他设备进行数据交换和通信。 软件组成: 该操作器的软件主要包括操作系统、应用程序和驱动程序等。操作系统负责设备的运行和管理;应用程序负责实现设备的测量、控制、数据处理等功能;驱动程序则是与硬件交互的桥梁,确保软件与硬件的正确对接。 使用方法: 使用该操作器前,需要连接相应的传感器和执行器,并设置正确的参数。通过触摸屏或键盘输入,可以设置控制目标、采样时间、控制算法等参数。在设备运行过程中,可以通过触摸屏或软件界面实时查看工业现场的数据和设备状态,并进行远程控制。Main features: * High-precision measurement and control: The operator has high-precision measurement and control functions, which can meet the needs of various industrial applications. * Easy to use: The operator is equipped with an intuitive graphical user interface, supporting touch screen and keyboard input, which is convenient for users to set and operate parameters. * Powerful data processing capability: The operator has built-in large-capacity memory and high-speed processing chip, which can quickly process various data and make real-time analysis and decision-making. * Strong compatibility: The operator supports a variety of communication protocols, such as Ethernet, serial interfaces, etc., to facilitate data exchange and communication with other devices. Application field: The operator is suitable for various industrial application scenarios, such as petroleum, chemical industry, electricity, metallurgy, textile, etc. It can achieve accurate control of various industrial processes and improve production efficiency and product quality. Working principle: ABB DSQC679 3HAC028357-001 operator collects data from the industrial site through sensors, processes and generates control instructions to achieve accurate control of industrial processes. The operator also has self-diagnosis and alarm functions, which can detect abnormal situations in time and take corresponding measures. Hardware composition: The operator is mainly composed of microprocessor, sensor, memory, communication interface, etc. Among them, the microprocessor is the core of the operator, which is responsible for data processing and instruction generation; the sensor is responsible for collecting data in the industrial field; the memory is used to store data and programs; and the communication interface is used for data exchange and communication with other devices. Software composition: The software of the operator mainly includes operating systems, applications and drivers. The operating system is responsible for the operation and management of the device; the application is responsible for the measurement, control, data processing and other functions of the device; the driver is the bridge to interact with the hardware to ensure the correct docking of software and hardware. Usage: Before using the operator, you need to connect the corresponding sensors and actuators and set the correct parameters. Through the touch screen or keyboard input, you can set parameters such as control target, sampling time, control algorithm, etc. During the operation of the device, you can view the data and equipment status of the industrial site in real time through the touch screen or software interface, and control it remotely.